Why Color PPF Is One of the Fastest-Growing Trends in Car Customization

- Jass

- Jan 7

- 3 min read

The rise of Color PPF is not driven by novelty or marketing. It is driven by increasingly educated customers who want more from vehicle customization.

Today’s customers expect:

Visual differentiation without permanent modification

Protection comparable to clear PPF

Stable color performance over time

Solutions that preserve resale value

As a result, many customers who previously chose vinyl—or clear PPF combined with repainting—are now actively requesting Color PPF. This shift in customer expectations is the primary force behind its rapid market growth.

A Mature Market: Why Now Is the Right Time

Early generations of Color PPF introduced the concept but not the consistency. First- and second-generation products often faced challenges such as color instability, adhesive failure, and difficult removal.

Today, Color PPF technology has matured.

Modern Color PPF benefits from:

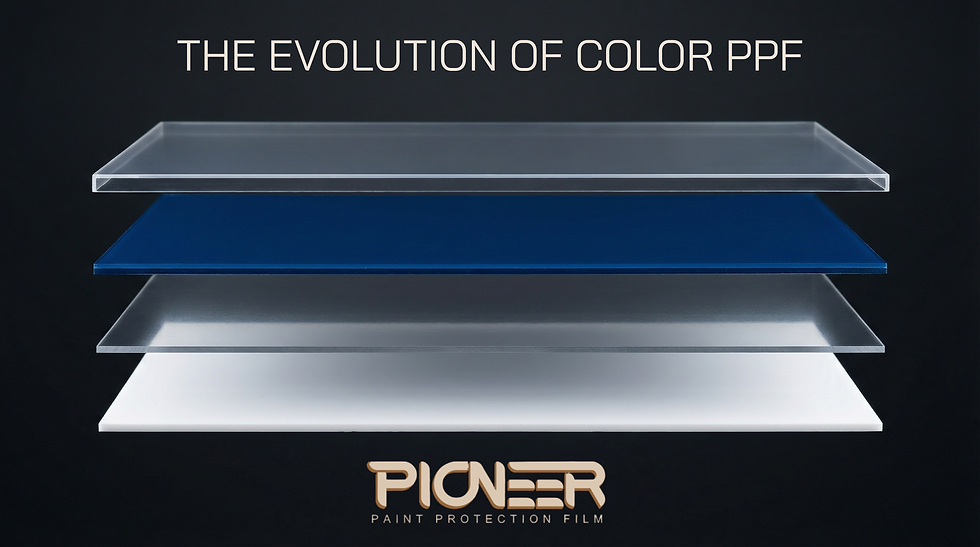

Refined layer architecture

Wide Range of color/texture choices

Improved UV resistance and color stability

Predictable long-term performance

Cleaner removal behavior

For detailing shops, this means entering the market after the major technical risks have been addressed, rather than during the experimental phase.

Clear PPF Customers Are Ready for the Upgrade

One of the strongest drivers of Color PPF growth is the existing clear PPF customer base.

Customers who already invest in clear PPF have demonstrated:

Budget readiness for premium protection

Long-term ownership mindset

Appreciation for durability and finish quality

For these customers, Color PPF represents a natural upgrade, not a substitute.

Color PPF allows shops to:

Offer significantly more visual options at a premium price point

Increase average job value without increasing installation time

Deliver customization without compromising protection

Instead of competing on price, detailing shops can expand upward, serving customers who already understand the value of PPF.

Color PPF vs Vinyl: A Practical Upgrade for Professionals

Vinyl wraps remain widely used, but their limitations are well understood by installers:

Fading over time

Noticeable color mismatch after partial replacement

Higher after-sales involvement

Shorter service life

From an operational standpoint, Color PPF offers clear advantages over vinyl:

Higher resistance to stone chips and abrasion

Better UV stability and long-term color consistency

Cleaner, residue-free removal

Fewer after-sales complaints

A key benefit is color consistency. High-quality Color PPF does not fade in the same way vinyl does. This means partial replacements remain visually seamless — an important advantage for both customer satisfaction and installer reputation.

Superior Texture on Special Finishes

Color PPF also delivers noticeable improvements in surface texture, particularly on special finishes.

On colors such as carbon fiber, satin, or textured effects, Color PPF provides:

Greater depth and realism

Smoother, more refined surface feel

Better consistency across panels

This is an area where vinyl often falls short, reinforcing Color PPF’s position as a premium solution.

Higher Margins Within the Same Installation Window

From a business perspective, Color PPF is highly efficient.

For most detailing shops:

Installation time is comparable to clear PPF or premium vinyl

Job value is higher

Revenue per hour increases without additional labor

This allows shops to improve margins while maintaining existing workflows — a critical advantage in a competitive market.

Fewer After-Sales Issues, Lower Long-Term Risk

After-sales service is often where vinyl jobs become costly.

Inferior vinyl and early-generation Color PPF products commonly result in:

Fading complaints

Adhesive failures

Difficult removal

Reputation damage

Modern Color PPF is designed to minimize these risks. Stable color performance and predictable removal behavior significantly reduce rework and warranty claims, improving long-term profitability.

Easy Transition for PPF and Vinyl Installers

Adopting Color PPF does not require reinventing the process.

Installation techniques are the same as clear PPF

Existing PPF installers can transition immediately

Vinyl installers can adapt quickly with minimal retraining

No major tooling changes or workflow disruptions are required, making Color PPF one of the easiest service upgrades available.

Choosing the Right Color PPF Matters

As demand grows, product quality varies widely.

Detailing shops should evaluate:

Color stability over time

Partial replacement behavior

Removal characteristics

Manufacturer support and warranty structure

Understanding the technical evolution of Color PPF helps installers avoid inferior products that may appear attractive initially but create long-term risk. For deeper technical context, refer to our previous article on the evolution of Color PPF technology.

A Strategic Upgrade for Modern Detailing Shops

Color PPF is not a short-term trend. It is a response to changing customer expectations and a mature technology solution.

For detailing shops focused on:

Higher margins

Time efficiency

Reduced after-sales exposure

Long-term customer trust

Color PPF represents a strategic, premium upgrade — and with technology now mature, now is the right time to adopt it.

Comments